Production environments demand accuracy that holds firm across extended output cycles. Buyers expect identical results whether ordering hundreds or thousands of units. Precision therefore becomes inseparable from operational discipline and measurable control. Industrial buyers increasingly rely on metal fabrication thailand to balance repeatable accuracy with dependable production scale.

Defining High Volume Fabrication Success

High volume fabrication succeeds when precision remains unchanged across repeated runs. Consistency depends on controlled inputs, verified processes, and predictable outcomes. Capacity alone never defines success without dependable dimensional accuracy.

Systems Driving Consistent Output Quality

Reliable fabrication depends on structured systems that guide every operation. These systems reduce variation by controlling execution details. Consistency improves when each stage follows documented expectations.

Process Governance Methods

Clear oversight keeps production behavior predictable throughout long runs.

- Defined tolerances for every fabrication stage

- Controlled sequencing between forming and finishing

- Verified checkpoints before batch progression

Quality Assurance Controls

Inspection frameworks prevent gradual deviations from accepted benchmarks.

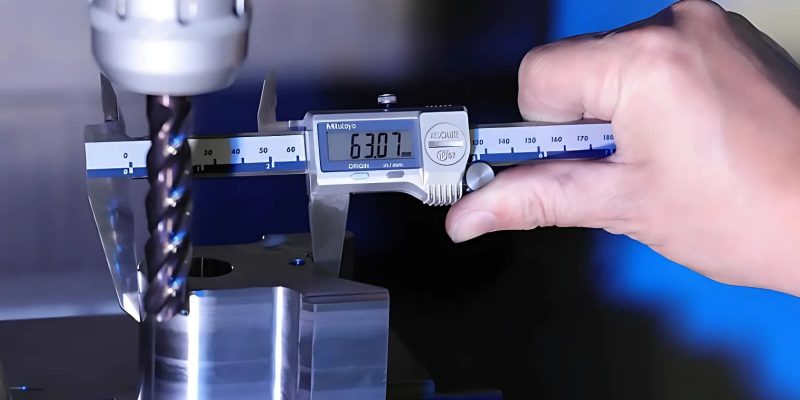

- Scheduled dimensional checks across batch intervals

- Visual verification aligned with customer specifications

- Documentation confirming repeatable acceptance outcomes

Together, these systems create dependable output confidence. Buyers gain assurance that repeated orders maintain identical standards.

How Precision Maintains Repeatable Results?

Precision ensures that output quality does not drift over time. Small deviations accumulate quickly during large production volumes. Tight control protects measurements from gradual inconsistencies. Manufacturers protect repeatability by isolating process variables early. Tool calibration, material positioning, and forming pressure remain fixed. These measures preserve identical outcomes across consecutive batches.

Operational Structures Supporting Scale

Scaling fabrication volume requires operational structure, not improvisation. Clear production frameworks keep expansion predictable. Structured planning reduces errors during extended manufacturing cycles.

Workflow Coordination Practices

Sequenced task execution prevents congestion and quality disruption.

- Balanced workload distribution across fabrication stations

- Defined handoff points between process stages

- Timing controls matching capacity with demand

Resource Allocation Standards

Stable resource planning supports uninterrupted production flow.

- Material staging aligned with output schedules

- Equipment readiness confirmed before run initiation

- Personnel assignments matched to process requirements

Operational planning within metal fabrication thailand supports controlled workflows that reduce variation across repeated manufacturing cycles. These structures allow scale growth without compromising output confidence.

Does Production Consistency Affect Buyer Confidence?

Yes, consistency directly influences buyer trust and ordering behavior. Predictable quality simplifies planning across procurement teams. Buyers value partners who deliver identical results without additional oversight.

Confidence strengthens when repeat orders require minimal revalidation. Clear consistency reduces approval delays and corrective communication. This reliability often becomes a deciding factor for long-term agreements.

Industrial Capacity Meeting Exacting Expectations

High volume fabrication succeeds through discipline rather than speed alone. Controlled execution allows capacity growth without measurement compromise. Buyers recognize value when every unit reflects identical workmanship.

Facilities that prioritize process clarity maintain credibility under pressure. Precision-focused operations reinforce trust across repeated engagements. Such capability supports demanding production schedules without introducing uncertainty.

Comments