You’re not running a hobby shop. You’re keeping a refinery, a chemical plant, or an exploration site alive. That means every second matters. So when something as simple as a wire connection gets exposed to dust, oil vapour, or heat, it’s not just annoying. It’s dangerous. It’s the start of a chain reaction you really don’t want to deal with. That’s where the electrical junction box comes in. It doesn’t look flashy, but it could be the one thing standing between your team and an unplanned shutdown.

Think It’s Just a Box? It’s Your First Line of Defence

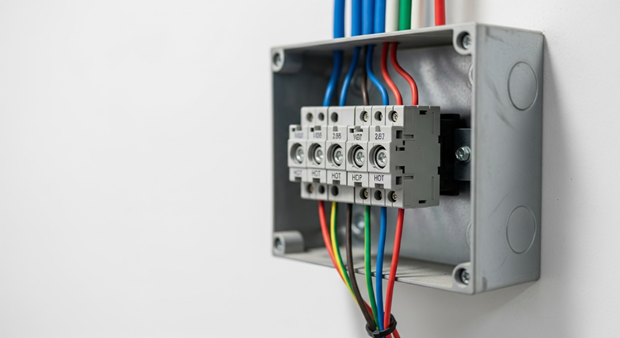

You deal with harsh environments daily—explosive atmospheres, corrosive fumes, vibration, moisture. The junction box absorbs those hits. It’s built to keep every wire dry, sealed, and secure, so one loose spark doesn’t become a disaster. A good box protects your plant’s heart and brain, shielding critical junctions from environmental abuse. Without that protection, even one exposed connection could cripple the system. Or worse, trigger a complete shutdown. You need electrical enclosures that stand up to the realities of your operation.

Wiring Chaos? This Box Brings Order to the Madness

Picture a wiring mess during an emergency. No labels. No layout. Just stress. You don’t have time to trace cables across hundreds of metres. With proper junction box installation, you get clarity. Wires meet where they should. Labels guide the way. You open the box, find the fault, fix it, and move on. No confusion. No wasted time. Every second saved during downtime means production continues—and profits stay intact.

Stop the Shutdown Spiral Before It Starts

Plant upgrades never stop. A new pump here, a sensor array there, maybe a better control cabinet. But adding components shouldn’t require complete rewiring or risk interrupting your entire operation. When industrial electrical boxes are part of the initial layout, you’ve already got tap-in points ready. You can make changes without tearing everything apart. It’s a smart, scalable approach that keeps your system flexible and running.

Fail Safety Checks and You Fail the Whole Plant

There’s no room for shortcuts when it comes to compliance. One missing safety feature, or one uncertified connection, and regulators might shut you down. That’s why explosion-proof enclosures, specifically designed for high-risk zones, are essential. Yes, they come at a higher cost. But the alternative? Fines, fires, or worse. These enclosures are your proof that safety comes first. They keep your plant compliant—and operational.

Catch Small Faults Now or Face a Big Breakdown Later

Electrical problems rarely scream for attention. They start small. A loose wire. A bit of moisture. Over time, those issues build. That’s why transparent covers, clear terminal blocks, and tidy internal layouts inside your electrical junction box matter so much. They make inspections faster and cleaner. When your team can spot early signs of trouble, you get ahead of failures—and avoid the kind of downtime that throws schedules off course.

Losing Data Could Be Worse Than Losing Power

Your decisions rely on real-time data—temperature, pressure, flow, alerts. If the data stops flowing, so does your insight. Power and data lines housed in separate compartments within a junction box prevent signal disruption. That means your monitoring stays intact. The plant stays visible. And your team keeps control, no matter the conditions.

Overheating? One Spark Could Shut It All Down

You’ve seen what heat can do to electrical systems. Inside poorly ventilated boxes, things escalate quickly. Temperatures rise, and wires suffer. Top-tier enclosures are made to manage that. Some feature ventilation or heat-dissipating materials. And when you’re working in moisture-heavy areas, waterproof junction boxes offer an extra layer of protection. They keep things cool and safe inside—even when the outside is anything but.

When the Nearest Technician Is Hours Away, This Box Saves You

Remote sites can’t afford delays. You can’t wait hours for backup. When problems arise, you need answers fast. A junction box with clear labelling and accessible schematics gives your team the tools to troubleshoot without guesswork. No waiting. No phone calls. Just a straightforward system that works when you need it most.

Audits Coming? This One Box Can Save the Whole Inspection

Audits are stressful. Sometimes it’s not the big things that get flagged, but the little ones. Tangled wiring. Missing labels. Unclear documentation. Well-designed junction boxes simplify all of it. Neat, labelled connections show auditors your system’s under control. And when everything’s in place, the inspection becomes routine, not a threat.

Don’t Let Corrosion or Time Wear Down Your Defences

You can’t stop time, but you can prepare for it. Boxes built from stainless steel or polycarbonate do more than survive—they thrive. Whether you’re offshore or in a chemical plant, they won’t crack or warp under pressure. That durability means fewer replacements, fewer surprises, and far less downtime.

Ignore It and Regret It—This Box Holds It All Together

It’s tempting to focus on big equipment—turbines, control rooms, servers. But without the electrical junction box holding those systems together, it all falls apart. These boxes aren’t showy, but they’re essential. They connect, protect, and future-proof your infrastructure. And when the pressure’s on, you need to trust that everything behind the scenes is working exactly as it should.

Comments